Every year, as winter sets in, headlines about deteriorating air quality in Delhi capture the attention of the media, researchers, government officials, and citizens alike. The pervasive issue of pollution in Delhi intensifies during the winter months due to the widespread practice of stubble burning in neighbouring states, aggravated by unfavourable climatic conditions. Diverse figures emerge on the impact of stubble burning on Delhi’s air quality, where the range of stubble’s contribution to PM2.5 concentration spans from 1% to 58%. It is estimated that PM2.5 air pollution alone claimed approximately 54,000 lives in India's national capital in 2020. The economic toll of air pollution was equally alarming, resulting in estimated losses of 8.1 billion USD (58,895 crores), equivalent to 13% of Delhi's annual GDP.

As an urban planning and policy graduate, my inherent curiosity about the challenges faced by cities drew me to the critical issue of air quality. Fortunately, upon joining GDi, I got to work on one of the most discussed and formidable challenges – stubble burning, with the Government of Punjab.

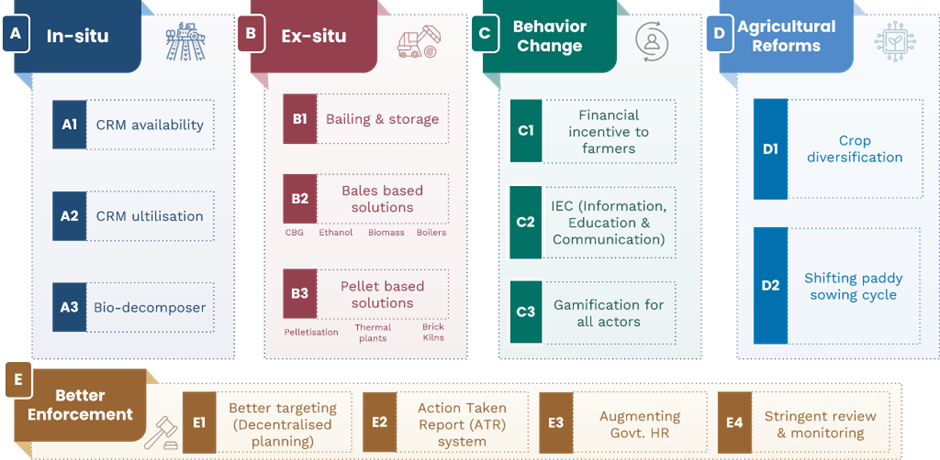

Punjab, a significant contributor to the issue, produces a staggering 20 million tonnes of paddy straw from agricultural land spanning 30 lakh hectares. Shockingly, over 50% of the paddy area is subjected to burning, resulting in the release of more than 30 million kilograms of particulate matter. Addressing such a colossal and intricate problem, with its impact ranging from atmospheric pollution to human health, soil degradation, food productivity, and climate change, demanded a holistic approach. Our initial step involved identifying the core issues that required focus, leading us to develop a comprehensive framework. Stubble burning isn't a challenge that can be tackled in isolation. Interventions such as crop diversification can reverberate across various sectors, impacting the public distribution system, farmers' income, amongst others

Overview of our work with the Government of Punjab

To reduce the stubble burning issue, GDi closely worked with the Govt. of Punjab and designed a multisectoral strategy spanning in-situ management, ex-situ management, review and monitoring systems, behavioural change, and decentralised planning. To meet our objectives, we engaged with diverse stakeholders, including the Chief Minister's office, the Chief Secretary’s office, the Agriculture Dept., the Punjab Pollution Control Board (PPCB), the Punjab Energy Development Agency (PEDA), the Punjab Remote Sensing Centre (PRSC) and many more. Amidst multiple initiatives, my particular focus zeroed in on in-situ management initiatives.

Our Approach for In-Situ Management

In-situ management involves handling the crop residue within the field itself using Crop Residue Management (CRM) machines. These machines handle crop residue by either retaining or incorporating it into the soil or collecting it for further utilisation, facilitated by suitable mechanisation inputs. Approximately 40% of the paddy area in Punjab (12 lakh hectares) is managed by in-situ techniques. Within this realm, our initiatives spanned government scheme process reengineering, scheme application redesign, machine gap analysis, and the meticulous planning and execution of machine distribution.

To enable the availability of CRM machines, the Ministry of Agriculture and Farmers’ Welfare, GoI, has been implementing a central sector scheme, 'Promotion of Agricultural Mechanization for In-Situ Management of Crop Residue in the States of Punjab, Haryana, Uttar Pradesh, and NCT of Delhi,' since 2018-19. This scheme offers financial assistance for CRM machines, covering 50% of the cost for individual farmers and 80% of the Custom Hiring Centres (CHCs). Over the period from 2018-19 to 2022-23, approx. ₹1400 crores have been allocated for providing subsidies to 1.2 lakh CRM machines in Punjab.

While the scheme had been in operation for four years, there was considerable room for improvement in ensuring the timely and effective delivery of machines. Identifying gaps in its implementation, we devised a roadmap and introduced procedural changes for more effective systemic implementation. Breaking down the scheme's implementation into 100 micro-steps, we identified challenges, associated stakeholders/departments, timelines for each step, and established milestones for each activity with a committed timeline. Through regular meetings and strategic engagement with government entities, we successfully accelerated the scheme's timelines, ensuring CRM machine distribution commenced at least one month earlier than in 2022.

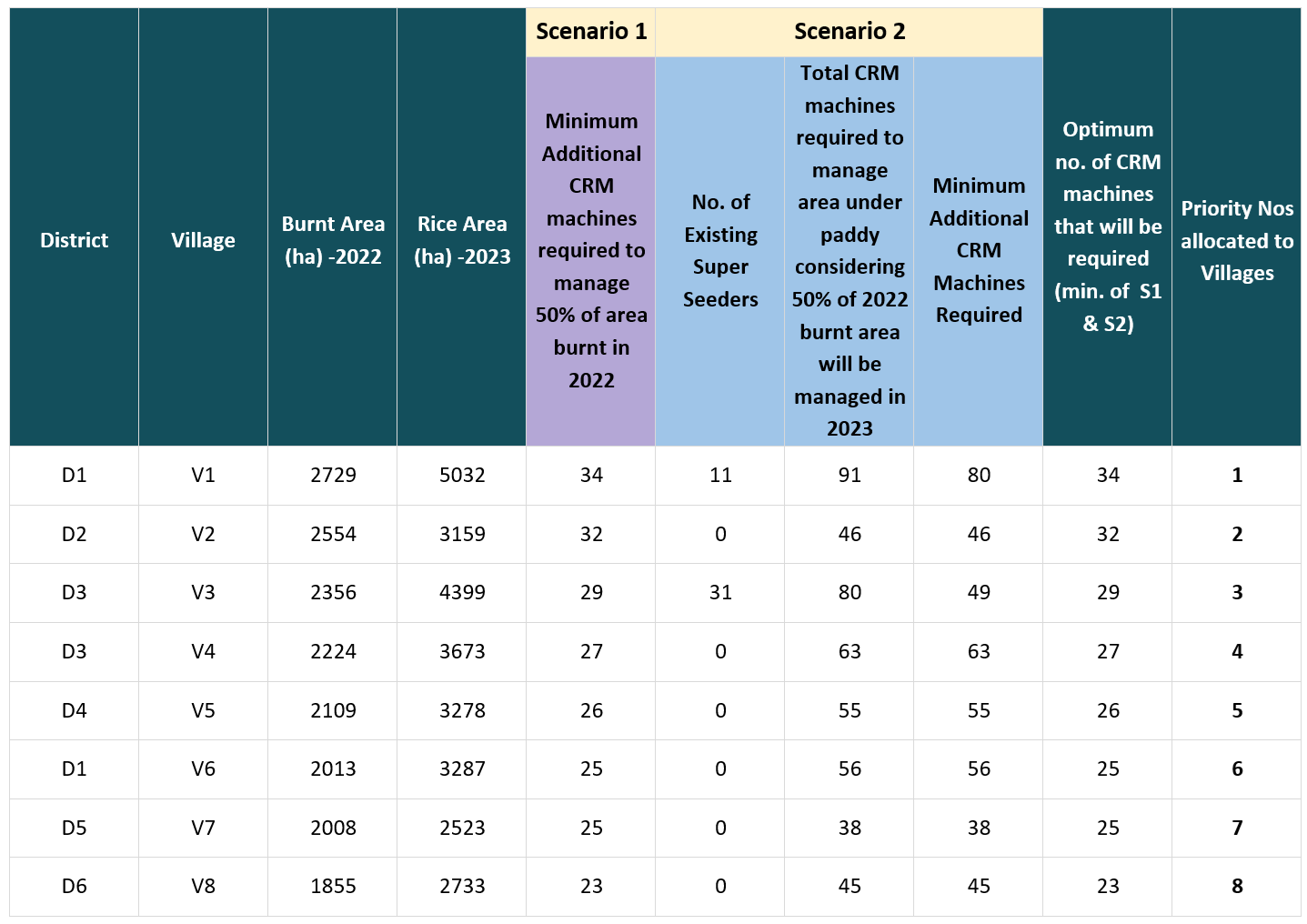

A significant departure from the past was re-engineering the machine distribution process. Until 2022, machine gap analysis was limited to the block level, and after demand analysis was completed, it remained unimplemented. In 2023, we calculated machine demand for each village by considering parameters such as the total area under paddy cultivation, the burnt area, and the availability and utilisation of existing CRM machines. The CAQM had set a target to reduce the burnt area by 50% in 2023. Therefore, the calculations for 2023-24 were made with this target in mind.

The requirement for machines was calculated at the village level by considering two scenarios. The minimum requirement from both scenarios was taken as the final requirement. Based on the number of optimal machines required, the village priority was assigned from 1 to 12,984, with 1 being the highest priority village and 12,984 being the lowest. The following table explains the scenarios considered to calculate the village-level CRM machine demand.

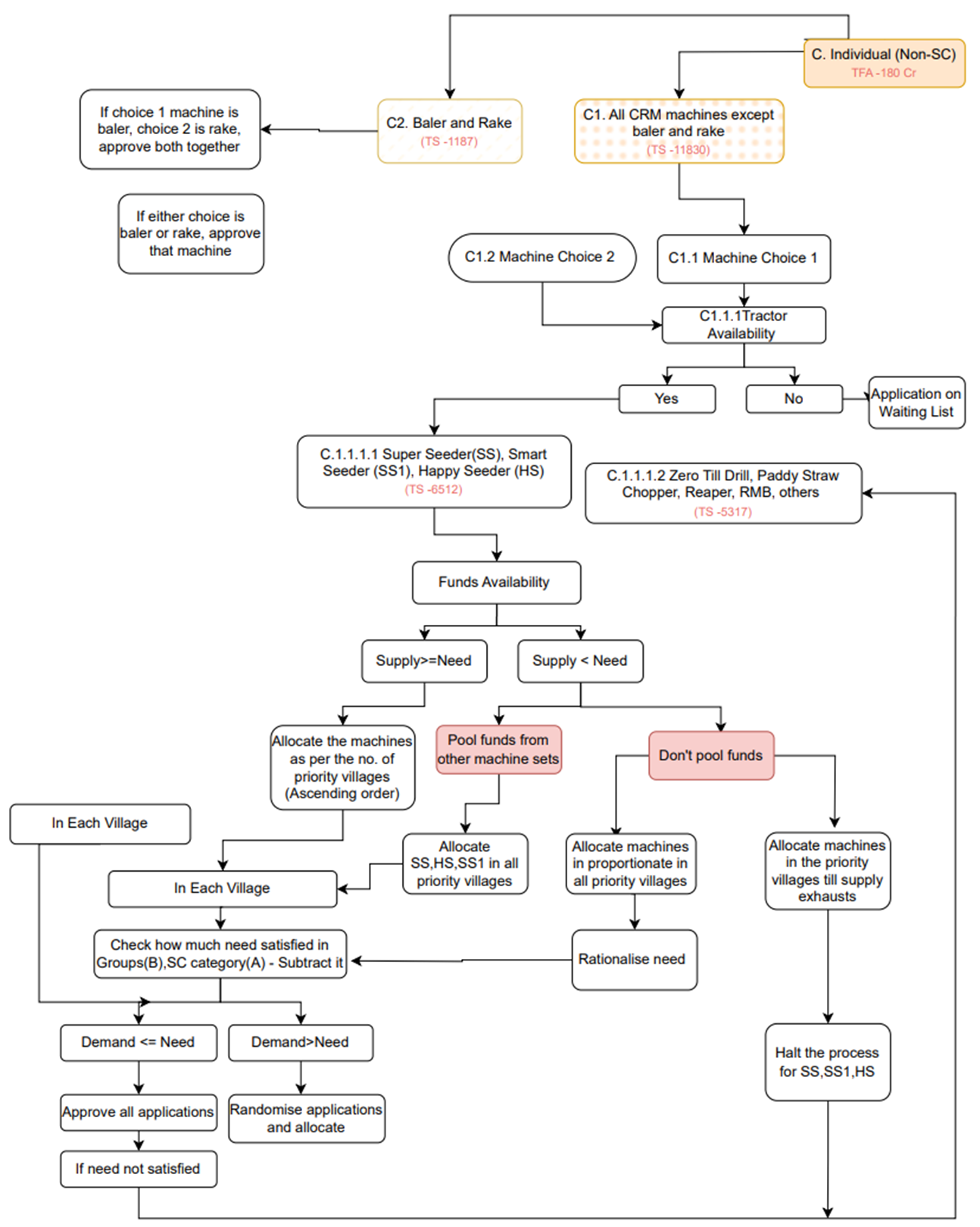

The next challenge was implementing this analysis on the ground, considering that the scheme budget allowed the distribution of only 23,000 machines, while 1 lakh applications were received. Till 2022, machines were allocated through a lottery system in each district, where officials randomly assigned machines to applicants. (If you are lucky, you get the CRM machine). To ensure CRM machines reached priority villages, we designed a system-based algorithm.

Designing the algorithm posed significant challenges due to the influence of multiple criteria. The distribution of machines had to be managed across 13 types (In-situ and ex-situ), application categories (Individual and Custom Hiring Centres (CHCs)), and general and SC categories as the budget was earmarked. The CHCs encompass panchayats, cooperative societies, registered farmer’s groups, rural entrepreneurs, and farmer-producer organisations. The model design underwent several iterations, considering factors such as fund availability, primary machine type, fund demand-supply analysis, tractor availability with farmers, etc. After numerous refinements, and consultations with senior officials and Agriculture Dept., the most optimal model was finalised. The model was calibrated to ensure the inclusion of special requirements in specific districts.

Challenges faced during the process

The entire process, from convincing the Agriculture Department to accepting innovation to actualising the implementation of the model, encountered resistance due to the reluctance to adopt new approaches. Once the algorithm was finalised, we worked with a team of developers, integrating the algorithm and the datasets into the existing CRM machine application portal. Additionally, finalizing the datasets required extensive pre-work, and discrepancies in village names necessitated a fuzzy mapping exercise.

Key Achievements

Despite the challenges faced, the model was utilised by the 23 districts to conduct the lottery, resulting in the allocation of 24,000 machines. The entire reengineering process enabled the achievement of the following outputs -

i) Targeted Distribution: Machines allocated to the villages where they were most needed

ii) Uniform Selection Process in all the districts: Machine allocation lottery process was consistent across the districts and a fair selection process was ensured as compared to the earlier random allocation

iii) Effective Fund Utilisation: Facilitated optimal allocation of funds by prioritising primary CRM machines and the most active custom hiring centres

iv) Timely Allocation: Improved machine allocation to farmers by 2-3 weeks compared to the previous year

v) Burnt Area Reduction in Priority Villages : In the top 250 priority villages, 3,289 applications for CRM machines were received from 213 villages (85%); 63 of these villages fulfilled their CRM machinery requirement, with 71% experiencing a reduction in burnt area

My Key Takeaways from the Re-Engineering Journey

Reflecting on this journey, I have gained invaluable insights through the challenges and successes encountered along the way.

i) Perseverance is the key: In a government setup, tangible changes take time and encounter resistance. However, persistent efforts can significantly contribute to achieving the goals.

ii) Modest yet impactful interventions across initiatives result in substantial change: While big innovations can be transformative, small procedural interventions across different work streams lead to on-ground change.

iii) Staying emotionally resilient solves half the problems: Sometimes, while working with the government or certain stakeholders, the process can become frustrating. However, bouncing back with a positive mindset is the way forward.

iv) Adopting a multi-pronged strategy in stakeholder management helps in effective implementation: Working with the government necessitates pulling every lever possible, and ensuring constant engagement with stakeholders at all levels, from senior to junior to turn ideas into action.

My experience working on stubble management in Punjab serves as a powerful reminder of the impact well-orchestrated interventions can have on governance. This initiative has highlighted the critical roles of data-driven decision-making and stakeholder engagement in driving change, as well as the power of perseverance. By rethinking CRM machine distribution, we have taken a significant step towards effective and sustainable stubble management